The city of Fes is Morocco’s third largest city and home to one of the most unreal medinas you’ll find in the country. With over 9,000 alleyways filled to the brim with shops selling just about everything you can imagine, it’s seriously a travelers dream.

Part of what makes Fes’ medina so fantastic is some of the historical sites that fall within the walls, including the famous leather tanneries. Fes is home to three ancient tanneries, but the most famous is Chouara which is almost a thousand years old.

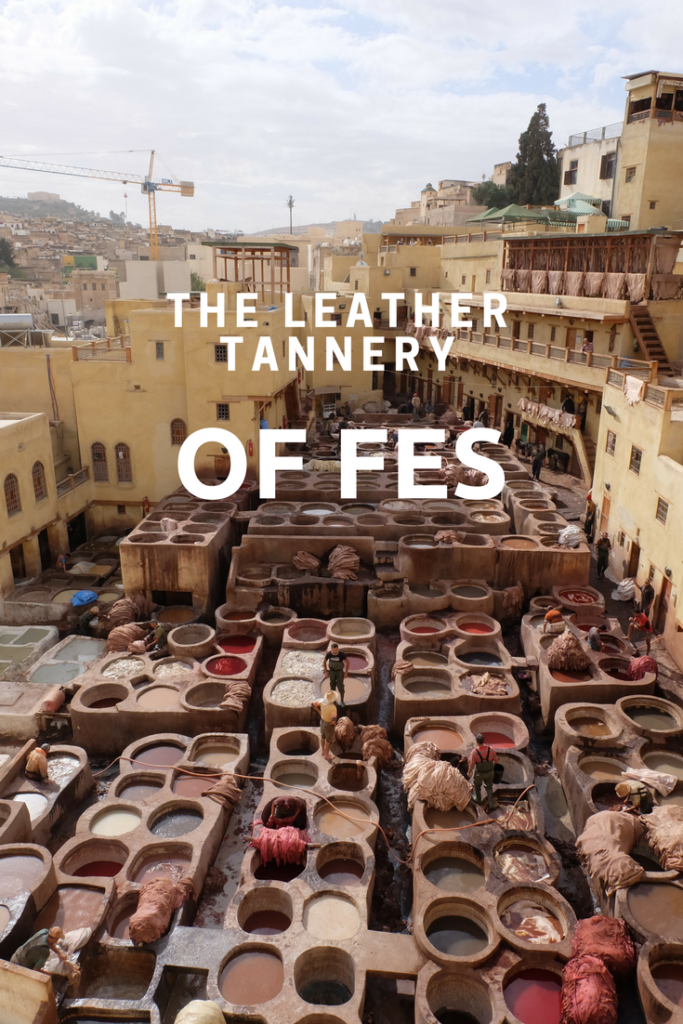

Fes’ tanneries consist of several stone vessels that are filled with a range of natural dyes and various liquids. Dozens of men are often in and out of standing waist deep in the vessels, working under the hot Moroccan sun to prepare the animals hides soaking in each vessel. The tanneries work with a variety of different hides from cows, sheep, goat and camel, and turn them into the beautiful leather products you see lining the streets of Fes.

The first soak: Urine

At the Chouara Tannery, hides are soaked in a combination of liquids that may surprise you, but the process used in the tanneries hasn’t changed much at all since the medieval times. The hides are first soaked in a mixture of cow urine, quicklime, water and salt. This mixture will help break down the hide and loosen excess fat, flesh and hair (I know, gross). The hide will remain in this liquid for two to three days and then the workers will scrape away the remaining hair and fat to prepare the hide for dyeing.

The second soak: Poop

Usually the hides are then soaked in another vessel containing water and pigeon poop. As you can notice so far, this process is very natural and there are no chemicals used. The pigeon poop contains ammonia that helps soften the hides to prepare them for dyeing. This process helps the hides absorb the dye. The craziest part? It’s someones job to knead the hides for up to three hours in this stage of soaking, so the hide achieves the desired softness. That’s right, you can’t complain about your boring desk job anymore!

The third soak: Dye!

After the softening happens, the hides are then ready to be dyed! The hides are places in vessels that contain natural vegetable dyes such as poppy flowers for red leather, indigo for blue, mint for green, and the most expensive leather products, saffron for yellow.

Time to dry & sell

After the hide is dyed, it will be taken out to dry in the sun and then the finished leather will be sold to craftsmen who make all the beautiful leather products you’ll find on the streets of Fes and beyond. Products range from colourful slippers, wallets, handbags, furniture, etc. These products are all created by manual labor and there is no modern machinery used.

As you can see, this process is incredibly unique and it’s hard to imagine that people still work among these tanneries, waist deep in poo, urine and everything in between. To visit one of the unique tanneries and see it for yourself, you’ll need to enter one of the leather shops that surround the tannery. Mostly all of these large shops have a terrace where you can see a panoramic view of the tannery. And don’t worry, usually they’ll supply you with some fresh mint to hold near your nose to help with the scent.

Other content on Morocco to read:

- Highlights of Morocco

- Packing for Morocco

- 2 Weeks in Morocco (Video)

- How to Spend One Week in Morocco

Pin the below image to save this for later!

No Comments